Inverter-Control Integrated Machines are redefining industrial operations, offering unparalleled control and efficiency in energy management and automation systems.

Industrial Features:

- Robust Build Quality

Designed for demanding environments, these systems are built with durability in mind, capable of withstanding high temperatures, dust, and vibrations. - Multi-Functional Capabilities

Many machines integrate additional features like data logging, fault diagnostics, and programmable logic control (PLC) functionalities. - High Power Density

With advanced engineering, these systems deliver significant power output relative to their size, making them suitable for high-demand applications.

Applications in Industry:

- Manufacturing

They optimize energy use in industrial processes, ensuring minimal waste and maximum efficiency. Applications include powering motor drives, conveyor systems, and robotics. - Energy Backup Solutions

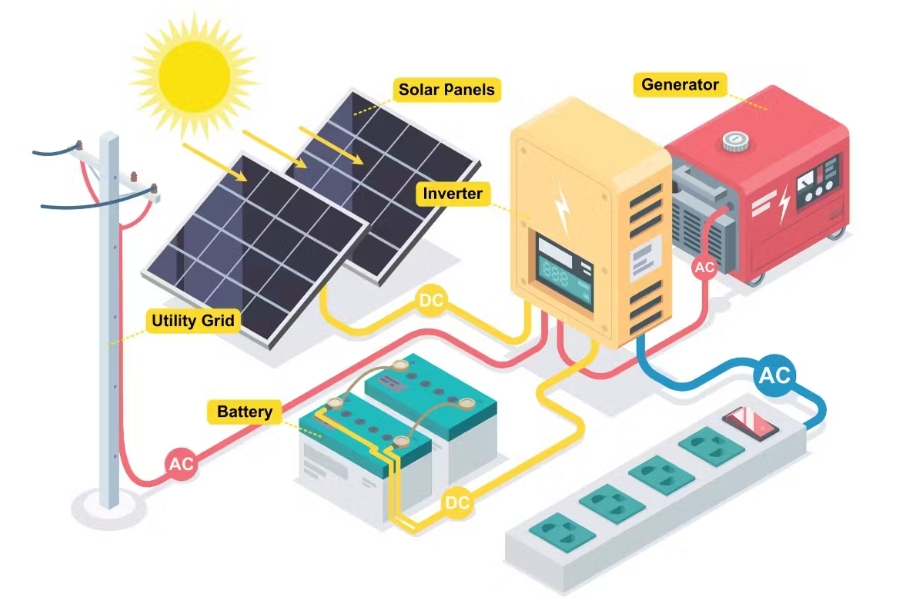

Inverter-control integrated systems are increasingly used in industries requiring uninterrupted power supply, such as data centers and hospitals. - Renewable Energy Integration

Industries incorporating renewable energy sources benefit from these machines’ seamless energy management capabilities. - Smart Grids

With the ability to interface with IoT and smart grid technologies, these systems enable predictive maintenance and adaptive energy distribution.

Inverter-Control Integrated Machines are not just a tool for energy conversion but a sophisticated system that enhances operational efficiency and sustainability in modern industries. Their versatility ensures their relevance across diverse industrial applications, paving the way for smarter, greener technologies.