Lead-acid batteries are widely used in various applications, including automotive, energy storage systems, and backup power supplies. Ensuring their performance and reliability often requires regular capacity testing. This article outlines the primary methods used to test the capacity of lead-acid batteries.

1. Constant Current Discharge Test

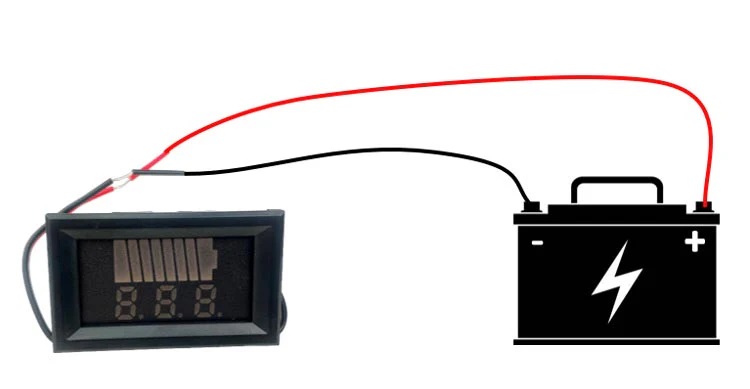

The constant current discharge test is the most commonly used method for determining the capacity of lead-acid batteries. It involves discharging the battery at a constant current until it reaches a predetermined cut-off voltage. The total discharge time is recorded and used to calculate the battery’s capacity, typically measured in ampere-hours (Ah).

Steps:

- Fully charge the battery to its rated capacity.

- Discharge the battery at a specified constant current (e.g., C/20, where C is the rated capacity).

- Stop the discharge once the battery voltage drops to the cut-off voltage, often set at 1.75V per cell.

- Calculate the capacity using the formula:

2. Constant Power Discharge Test

This method is particularly useful for batteries used in applications like uninterruptible power supplies (UPS). The battery is discharged at a constant power level until the cut-off voltage is reached.

Advantages:

- Simulates real-world operating conditions.

- Provides insight into how the battery performs under a constant load.

3. Internal Resistance Measurement

While not a direct measure of capacity, internal resistance testing can provide a good indication of a battery’s health and ability to deliver power. A high internal resistance often correlates with reduced capacity and performance.

Procedure:

- Use a specialized internal resistance tester.

- Measure the resistance during a brief, controlled load application.

- Compare the results to manufacturer specifications or baseline values.

By using these methods, users can ensure their lead-acid batteries remain reliable and efficient, helping to prevent unexpected failures.