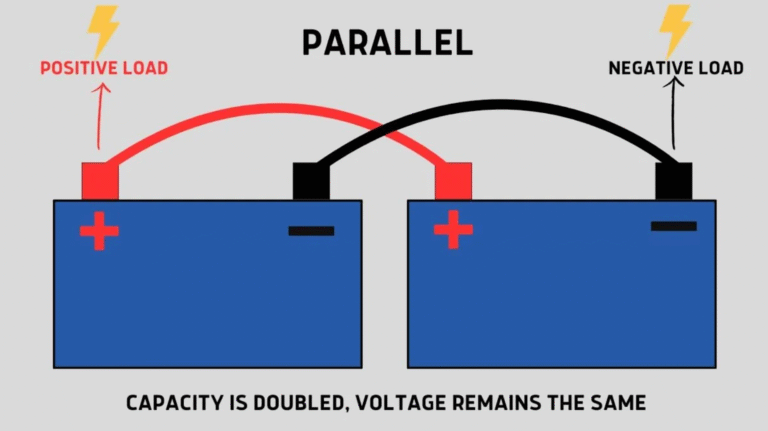

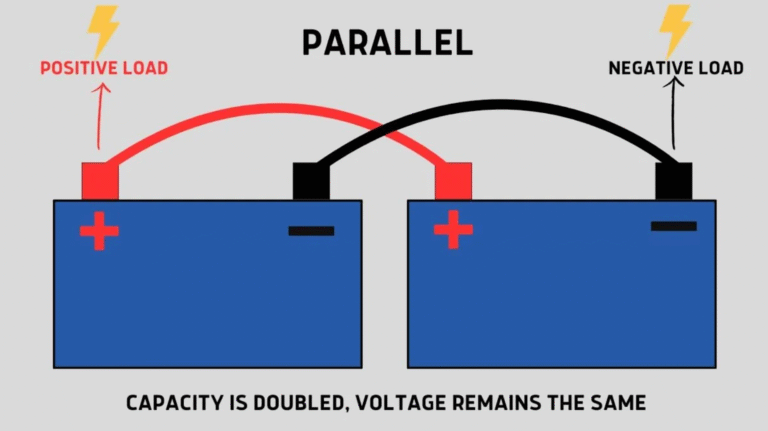

Parallel Connection of Lead-Acid Batteries in Energy Storage Systems: Benefits, Risks, and Best Practices

Primary Keywords:parallel lead acid batteries, lead acid battery parallel connection, energy storage batteries Introduction Parallel

Primary Keywords:parallel lead acid batteries, lead acid battery parallel connection, energy storage batteries Introduction Parallel

Sealing technologies for lead-acid batteries have evolved significantly, driven by the need for higher reliability,

The sealing quality of lead-acid batteries directly impacts their performance and lifespan. Despite advancements in

Sealing technology plays a critical role in ensuring the reliability, safety, and longevity of lead-acid

Winter maintenance is crucial for ensuring OPzS batteries continue to perform reliably even in low

Understanding the degradation mechanisms caused by high temperatures in OPzV batteries is key to improving

OPzV batteries, known for their reliability and long cycle life, are widely used in renewable

The capacity of lead-acid batteries can decrease significantly in winter due to lower temperatures. Here

Operating a lead-acid battery outside its specified temperature range can lead to several issues affecting

AGM (Absorbent Glass Mat) and Gel batteries are both types of Valve-Regulated Lead-Acid (VRLA) batteries,