The ability of lead-acid batteries to resist aging, or maintain their performance and capacity over time, is influenced by several key factors.

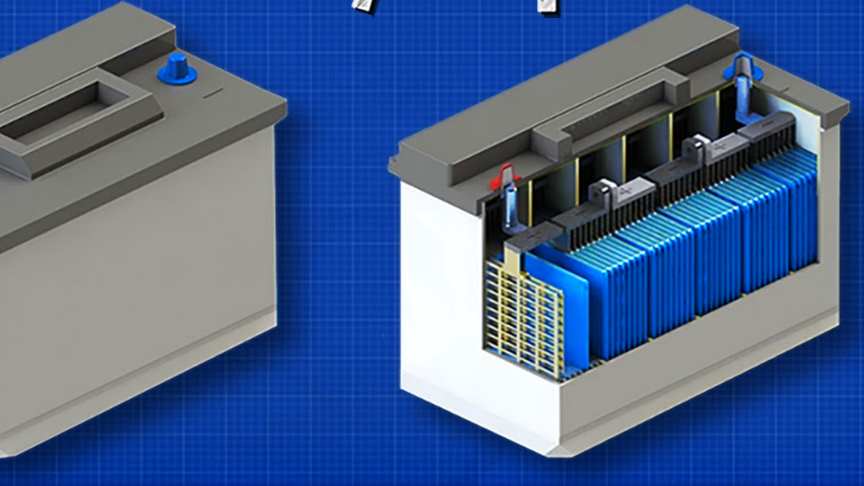

- Design and Construction: Lead-acid batteries are designed with specific materials and construction methods to withstand the stresses of charging and discharging cycles. Quality construction and robust design contribute to the battery’s longevity.

- Plate Composition and Purity: The composition and purity of the lead plates within the battery play a significant role in its performance and lifespan. Higher purity lead plates are less prone to degradation and sulfation, leading to improved longevity.

- Electrolyte Composition: The composition and quality of the electrolyte, typically a mixture of sulfuric acid and water, impact the battery’s performance and lifespan. Maintaining the correct electrolyte level and composition is crucial for optimal battery operation and longevity.

- Proper Charging and Maintenance: Lead-acid batteries require careful charging and maintenance to prevent degradation and extend their lifespan. Overcharging, undercharging, and improper maintenance practices can accelerate aging and reduce battery performance. Following manufacturer recommendations for charging methods and maintenance procedures is essential.

- Temperature Management: Lead-acid batteries perform best within a specific temperature range. Extreme temperatures can accelerate aging and reduce battery lifespan. Proper ventilation, insulation, and temperature monitoring help maintain optimal operating conditions and prolong battery life.

- Cycle Depth: Limiting the depth of discharge (DoD) during each cycle can help reduce stress on the battery and extend its lifespan. Shallow cycling, where the battery is not discharged fully during each cycle, is less damaging than deep cycling and helps preserve capacity over time.

- Equalization: Periodic equalization charging can help balance the cells within the battery and prevent the buildup of sulfation, which can reduce capacity and performance over time. Equalization charging involves temporarily overcharging the battery to ensure all cells receive a full charge.

- Quality Control and Testing: High-quality manufacturing processes, rigorous quality control measures, and thorough testing help ensure that lead-acid batteries meet performance specifications and longevity expectations. Proper storage, handling, and transportation also contribute to maintaining battery integrity.

By addressing these factors and implementing proper maintenance practices, lead-acid batteries can resist aging and maintain their performance and capacity over an extended period, providing reliable energy storage for various applications.