Lead-acid battery cables and copper plates serve different purposes within a battery system, and they differ in their construction, materials, and functions. Here’s a breakdown of their differences.

- Material Composition:

- Lead-Acid Battery Cable: Lead-acid battery cables are typically made of stranded copper conductors surrounded by a protective insulation material, such as PVC (Polyvinyl Chloride) or XLPE (Cross-Linked Polyethylene). The conductors are usually tin-plated to improve corrosion resistance.

- Copper Plate: Copper plates, also known as copper busbars or copper terminals, are solid pieces of copper metal. They are not typically insulated and are primarily used for electrical connections and conductivity.

- Function:

- Lead-Acid Battery Cable: Battery cables are used to connect batteries to electrical components within a system, such as inverters, chargers, or electrical loads. They serve as conductive pathways for electrical current to flow between the battery terminals and other components.

- Copper Plate: Copper plates are used as electrical conductors or terminals within a battery system. They provide a solid connection point for attaching battery cables, busbars, or other electrical components. Copper plates are often used for high-current applications where a robust electrical connection is required.

- Flexibility and Form:

- Lead-Acid Battery Cable: Battery cables are designed to be flexible and bendable, allowing them to be routed through tight spaces and around obstacles within a battery system. The stranded copper conductors provide flexibility while maintaining conductivity.

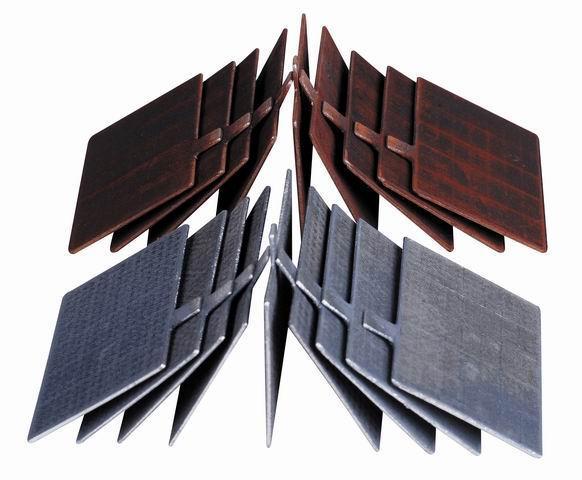

- Copper Plate: Copper plates are rigid and inflexible compared to battery cables. They are typically flat or shaped into specific configurations to accommodate the layout of a battery system. Copper plates come in various thicknesses and sizes depending on the current-carrying capacity required.

- Installation and Maintenance:

- Lead-Acid Battery Cable: Battery cables are relatively easy to install and maintain. They can be connected to battery terminals using compression or soldered connections and are often equipped with terminal lugs or connectors for easy attachment.

- Copper Plate: Copper plates require more careful installation and may involve drilling or welding to secure them in place. They also need periodic inspection for signs of corrosion or loosening connections to ensure proper electrical conductivity.

In summary, lead-acid battery cables and copper plates are essential components of a battery system, with cables providing flexible conductive pathways and plates serving as solid connection points for electrical components. They are designed to meet different requirements within a battery system and are selected based on factors such as current-carrying capacity, flexibility, and installation preferences.