Routine maintenance is essential for ensuring the optimal performance and longevity of lead-acid batteries. Here are the key maintenance tasks:

- Visual Inspection:

- Regularly inspect the batteries for any signs of physical damage, corrosion, or leaks. Look for cracks in the casing, bulging or swelling of the battery, and corrosion on terminals and connectors.

- Cleaning:

- Keep the battery and surrounding area clean and free from dirt, debris, and corrosion. Use a mixture of baking soda and water to neutralize any acid spills, and rinse thoroughly with clean water. Dry the battery and terminals completely after cleaning.

- Terminal Inspection and Tightening:

- Check the terminal connections for tightness and signs of corrosion. Clean the terminals and cable ends with a wire brush if necessary, and tighten the connections to ensure good electrical contact. Apply a thin coat of petroleum jelly or terminal grease to prevent corrosion.

- Electrolyte Level Check:

- For flooded lead-acid batteries, regularly check the electrolyte level in each cell. Add distilled water as needed to maintain the electrolyte at the recommended level, typically covering the plates by about 0.5 inch (12 mm).

- Specific Gravity Measurement:

- If the batteries are of the flooded type, periodically measure the specific gravity of the electrolyte using a hydrometer. This helps assess the state of charge and detect any cell imbalance. Refer to manufacturer guidelines for specific gravity values corresponding to battery state of charge.

- Equalization Charging:

- Perform equalization charging as recommended by the battery manufacturer. This involves temporarily applying a higher voltage to the battery to balance cell voltages and prevent stratification of electrolyte.

- Temperature Monitoring:

- Monitor the operating temperature of the batteries, as high temperatures can accelerate battery aging and reduce lifespan. Ensure proper ventilation and cooling in battery enclosures or rooms.

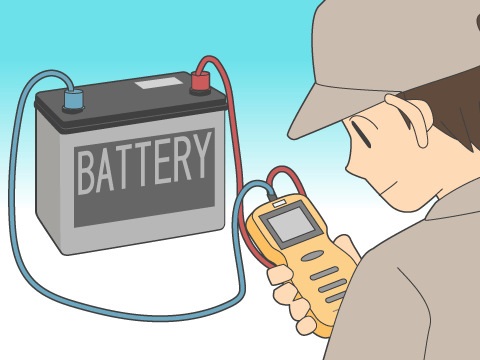

- Load Testing:

- Periodically conduct load tests to assess the battery’s capacity and performance under simulated operating conditions. This helps identify any deterioration in battery health and predict potential failures.

By performing these routine maintenance tasks on lead-acid batteries, you can maximize their reliability, lifespan, and overall performance, while minimizing the risk of unexpected failures or downtime.