Testing the quality of lead-acid batteries involves various methods to assess their performance, capacity, and health.

- Capacity Testing: This method involves fully charging the battery and then discharging it at a constant current rate while measuring the time it takes for the voltage to drop to a certain level. The capacity of the battery can be calculated based on the discharge time and current.

- Specific Gravity Testing: Lead-acid batteries use an electrolyte solution, typically sulfuric acid and water. The specific gravity of this electrolyte can indicate the state of charge of the battery. A hydrometer is used to measure the specific gravity of the electrolyte in each cell of the battery.

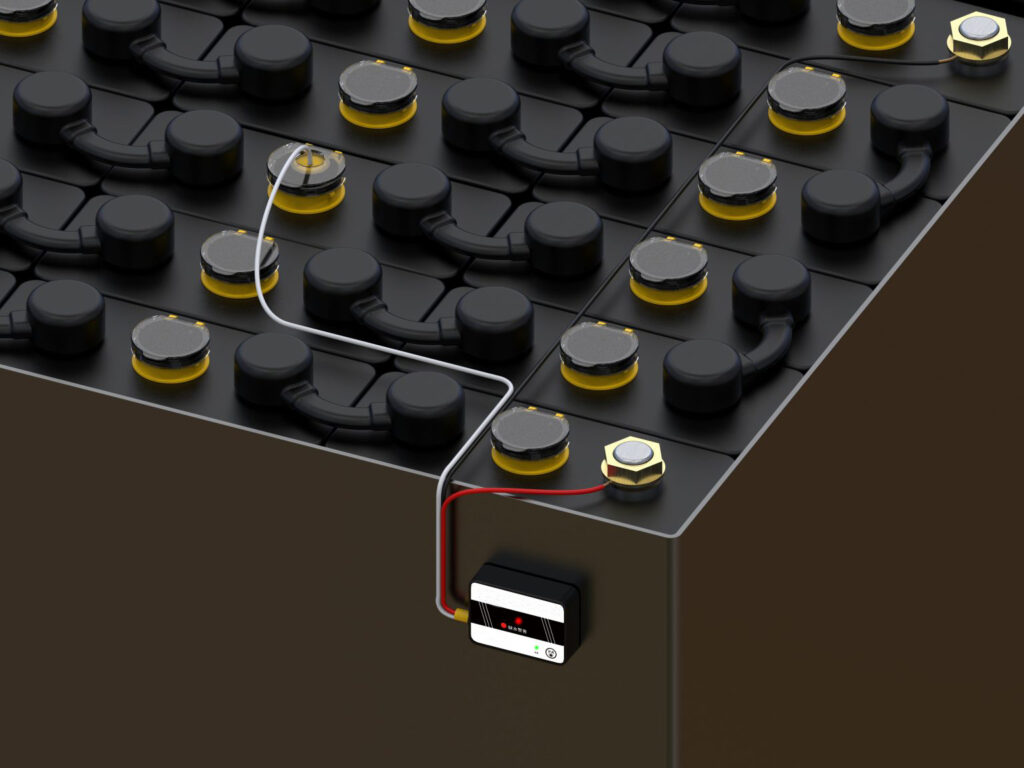

- Voltage Testing: Voltage testing is one of the simplest methods to assess the condition of a lead-acid battery. A voltmeter is used to measure the voltage across the terminals of the battery. This can give an indication of the state of charge and overall health of the battery.

- Internal Resistance Testing: Internal resistance can affect the performance of a battery. Higher internal resistance can lead to voltage drops and reduced capacity. Various methods, including impedance spectroscopy or direct current resistance measurements, can be used to assess internal resistance.

- Load Testing: Load testing involves applying a known load to the battery and monitoring its performance. This can help assess how the battery performs under real-world conditions and determine if it meets the required specifications.

- Electrolyte Analysis: Analyzing the electrolyte for contaminants or changes in composition can provide insights into the health of the battery. This can involve techniques such as titration or spectrophotometric analysis.

- Temperature Testing: Temperature can significantly impact the performance and lifespan of lead-acid batteries. Testing the battery under various temperature conditions can help assess its suitability for different applications and environments.

- Cycle Life Testing: This involves subjecting the battery to repeated charge and discharge cycles under controlled conditions to simulate its expected lifespan. Monitoring parameters such as capacity retention and internal resistance can provide insights into the battery’s long-term performance.

- Visual Inspection: Simple visual inspection can also provide valuable information about the condition of the battery, including signs of physical damage, corrosion, or leakage.

- Accelerated Aging Testing: Subjecting the battery to accelerated aging conditions, such as elevated temperature or overcharging, can help simulate long-term usage and assess its durability and reliability.

These testing methods are often used in combination to comprehensively evaluate the quality and performance of lead-acid batteries. The specific tests chosen may depend on factors such as the intended application of the battery and the level of detail required in the assessment.