Causes of Sulfation

- Extended Periods of Discharge: Leaving a lead-acid battery in a discharged state for long periods allows lead sulfate to crystallize and harden.

- Undercharging: Regularly not fully charging the battery can lead to partial sulfation over time.

- Low Electrolyte Levels: Insufficient electrolyte can expose the plates to air, leading to sulfation.

- High Temperatures: Elevated temperatures can accelerate the sulfation process.

Prevention and Reversal

Prevention:

- Regular Charging: Keep the battery fully charged whenever possible. Avoid deep discharges.

- Maintenance Charging: Use a maintenance charger or a battery tender to keep the battery charged during periods of inactivity.

- Proper Storage: Store batteries in a cool, dry place and check them periodically.

Reversal:

- Desulfation Chargers: Specialized chargers can sometimes reverse sulfation by applying high-frequency pulses to break down lead sulfate crystals.

- Equalization Charge: Occasionally, performing an equalization charge (controlled overcharge) can help to convert some of the sulfate back into active material, although this should be done carefully to avoid damage.

Conclusion

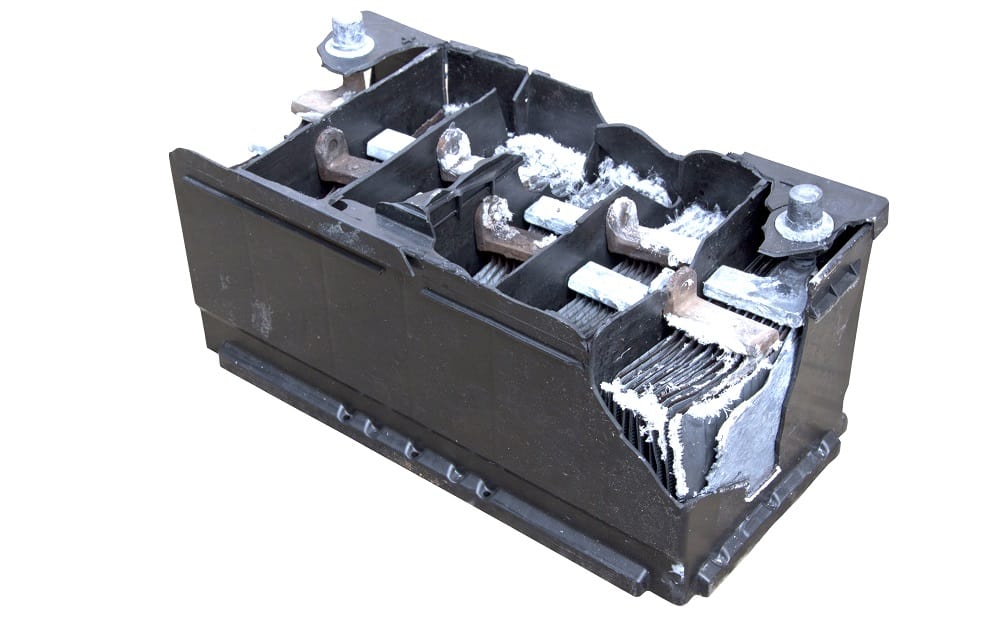

Hardened lead sulfate on the battery plates is a detrimental condition that severely impacts the performance and longevity of lead-acid batteries. Prevention through proper maintenance and charging practices is crucial, while some methods exist to attempt partial reversal if sulfation occurs. Understanding these aspects can help in maintaining the health and efficiency of lead-acid batteries.