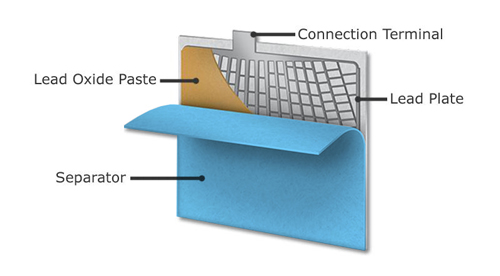

Lead-acid batteries consist of positive and negative plates immersed in an electrolyte. The design and composition of these plates are critical to the performance and characteristics of the battery.

Positive Plates:

- Material Composition:

- Positive plates are typically made of lead dioxide (PbO2) in a grid structure. The grid is often made of a lead-antimony alloy, although lead-calcium alloys are used in some applications for reduced water loss.

- Active Material Density:

- The positive plates should have a sufficient density of lead dioxide to maximize the energy storage capacity of the battery.

- Structure and Pasting:

- The paste of lead dioxide is applied to the positive grid structure, and the plates undergo a forming process to ensure proper adhesion and distribution of the active material.

- Perforations or Pores:

- Positive plates may have perforations or pores in the grid structure to allow for the expansion and contraction of the active material during charge and discharge cycles.

Negative Plates:

- Material Composition:

- Negative plates are typically made of sponge lead (Pb) in a grid structure. Like the positive plates, the grid may be composed of lead-antimony or lead-calcium alloys.

- Active Material Density:

- The negative plates should have a sufficient density of sponge lead to maximize the energy storage capacity and facilitate the electrochemical reactions during the battery’s operation.

- Structure and Pasting:

- The paste of sponge lead is applied to the negative grid structure, and the plates undergo a forming process to ensure proper adhesion and distribution of the active material.

- Perforations or Pores:

- Similar to positive plates, negative plates may have perforations or pores in the grid structure to accommodate the expansion and contraction of the active material during charge and discharge cycles.

Common Plate Requirements:

- Balance and Symmetry:

- Both positive and negative plates should be balanced and symmetrical to ensure uniform performance and longevity of the battery.

- Grid Alloy:

- The alloy used for the grid structure should be selected based on the desired characteristics of the battery, such as cycle life, water loss, and resistance to corrosion.

- Pasting Density:

- The density of the pasted active material on the grids should be controlled to optimize the performance and capacity of the battery.

- Plate Thickness:

- The thickness of the plates is an important factor influencing the structural integrity and overall performance of the battery.

- Formation Process:

- The positive and negative plates undergo a formation process during manufacturing, involving controlled charging and discharging cycles to convert the active materials into their stable forms.

Optimizing these plate requirements ensures that the lead-acid battery can deliver the desired performance characteristics, including capacity, cycle life, and resistance to factors like sulfation and grid corrosion.