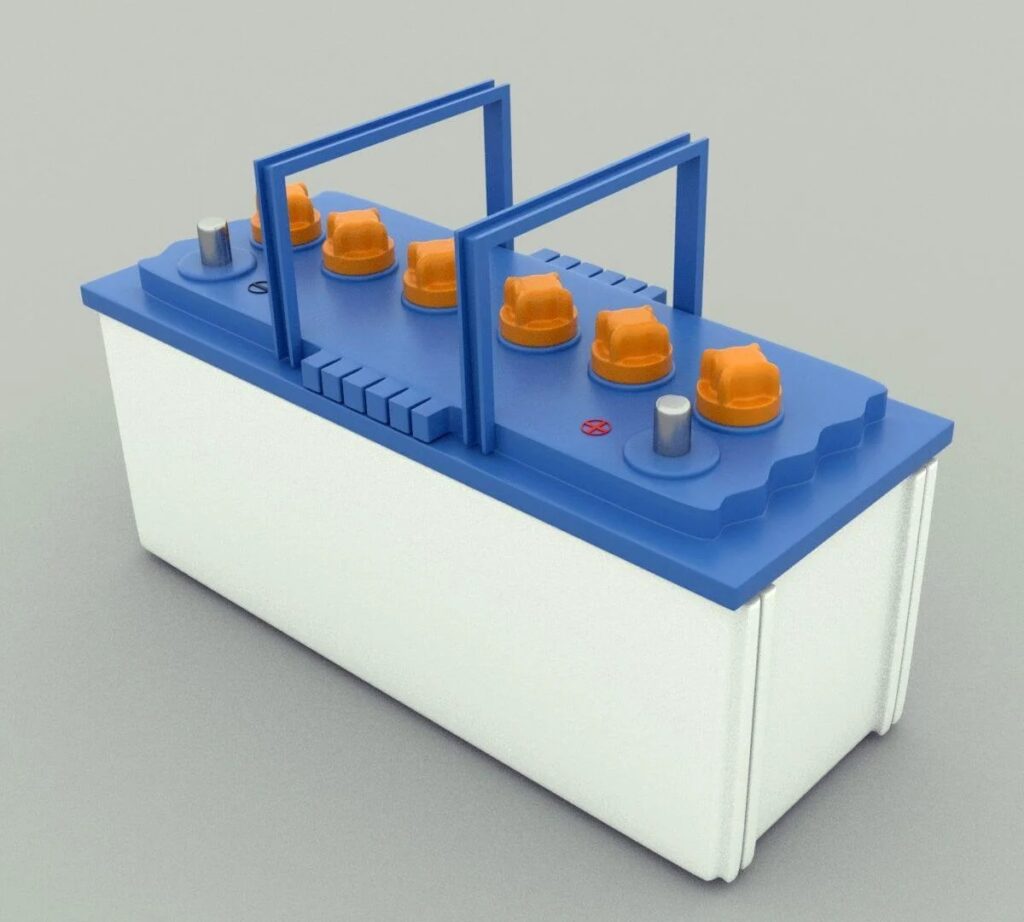

Lead-acid battery casings play a crucial role in ensuring the safety and functionality of the batteries. The requirements for lead-acid battery casings are typically governed by industry standards and regulations.

- Material and Construction:

- Casings are often made of durable and corrosion-resistant materials, such as high-density polyethylene (HDPE) plastic. The material should be capable of withstanding the chemicals present in the battery electrolyte.

- Sealing and Ventilation:

- Casings must be sealed to prevent leakage of electrolyte and to contain any gasses generated during battery operation. Adequate ventilation is also essential to allow the release of gases, particularly hydrogen, during charging.

- Resistance to Impact and Vibration:

- Casings should be designed to resist impact and vibration, especially in applications like automotive batteries where the battery may experience movement and shocks.

- Acid Resistance:

- The casing material must be resistant to the corrosive effects of sulfuric acid, which is the electrolyte used in lead-acid batteries. This helps prevent the casing from degrading over time due to exposure to the acid.

- Flame Retardancy:

- Casings are often designed to be flame-retardant to enhance safety. This is particularly important in case of potential short circuits or other malfunctions that might lead to overheating.

- Design for Easy Maintenance:

- Casings may include features that allow for easy maintenance, such as removable caps or covers for checking and replenishing electrolyte levels. This is important for ensuring the longevity and proper functioning of the battery.

- Compliance with Regulations:

- Manufacturers must adhere to industry and safety standards and regulations governing the design and construction of lead-acid batteries. These standards may vary by region, and compliance is essential for market acceptance and safety.

- Labeling and Marking:

- Casings should be clearly labeled with relevant information, including safety warnings, recycling instructions, and capacity specifications. Proper labeling ensures that users are aware of the necessary precautions and handling procedures.

- Environmental Considerations:

- Manufacturers may consider environmental aspects in the design of casings, such as using recyclable materials and ensuring compliance with environmental regulations for battery disposal and recycling.

It’s important to note that specific requirements may vary depending on the type of lead-acid battery (e.g., automotive, stationary) and the intended application.