The term “PACK” in the context of lithium battery packs usually refers to the process of assembling and packaging individual cells into a functional battery pack. The PACK process involves several key steps to ensure the safe and efficient integration of lithium-ion cells into a final product.

1. Planning and Design:

- Define the specifications and requirements of the lithium battery pack based on the intended application. Determine the desired voltage, capacity, and physical dimensions. Plan the arrangement of cells, wiring, and other components within the pack.

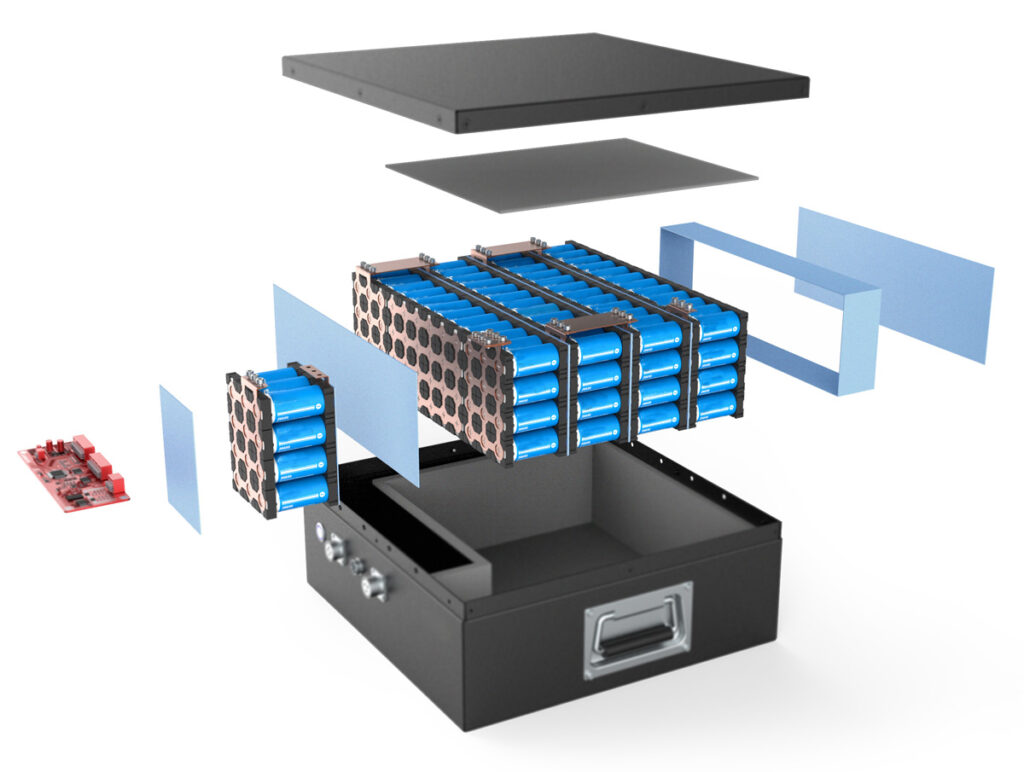

2. Assembly of Cells:

- Select and assemble individual lithium-ion cells according to the planned configuration (series and parallel connections). Use appropriate methods, such as spot welding or soldering, to connect cells while avoiding damage to the cells.

3. Battery Management System (BMS) Integration:

- Install a Battery Management System (BMS) if required. The BMS monitors and manages the performance of individual cells, ensuring balanced charging and discharging, temperature control, and overall safety.

4. Wiring and Interconnections:

- Connect the cells in series and parallel according to the design. Use properly sized and rated wires for both series and parallel connections. Ensure that the wiring is well-insulated to prevent short circuits and other safety hazards.

5. Thermal Management:

- Incorporate a thermal management system to dissipate heat generated during charging and discharging. This may include heat sinks, fans, or other cooling methods to maintain optimal operating temperatures and prevent overheating.

6. Encapsulation and Insulation:

- Encapsulate the assembled cells, wiring, and components in a protective casing. Ensure that the casing provides electrical insulation, protection against physical damage, and prevents the ingress of moisture or contaminants.

7. Testing and Quality Control:

- Conduct thorough testing to verify the functionality and safety of the battery pack. This may include voltage testing, capacity testing, thermal testing, and other performance checks. Implement quality control measures to identify and rectify any manufacturing defects.

8. Final Assembly:

- Complete the final assembly of the battery pack, including the installation of any external connectors, indicators, or other features. Ensure that all components are securely in place, and the pack is ready for integration into the final product.

9. Packaging:

- Package the assembled battery pack in a suitable enclosure or casing, considering the specific requirements of the application. The packaging should provide further protection against external elements and mechanical stress.

10. Documentation and Compliance: – Prepare documentation that includes specifications, safety guidelines, and compliance with relevant standards and regulations. Ensure that the battery pack meets industry and safety standards.

11. Shipping and Distribution: – If applicable, prepare the battery packs for shipping and distribution, adhering to regulations regarding the transportation of lithium-ion batteries. Include proper labeling and documentation for handling and disposal.

The PACK process may vary slightly depending on the specific requirements of the application and the industry standards followed by the manufacturer. It is essential to follow safety guidelines, adhere to industry standards, and comply with relevant regulations to ensure the quality, reliability, and safety of lithium battery packs.